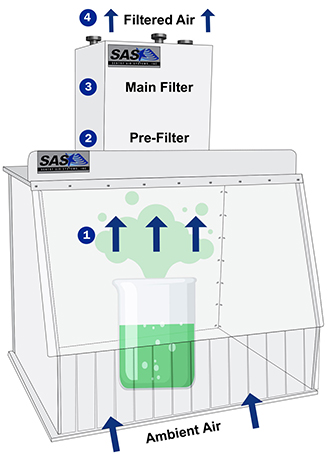

A ductless fume hood is a contained working space that uses powerful negative airflow to pull harmful fumes, vapors or particulate away from the operator’s respiratory zone and protects the operator and the environment from exposure.

How does a Ductless Fume Hood work?

Ambient Air is drawn into the hood and mixed with fumes, vapors or particulates emitted from the process.

The air within the hood is processed through a pre-filter where some particles are captured.

Air is filtered through the main filter (HEPA, ULPA, ASHRAE, Activated Carbon or Specialty Blended).

Filtered air is released back into the room eliminating the need for duct work.

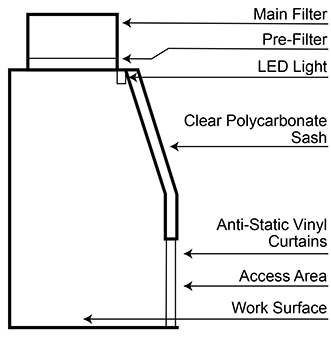

Anatomy of a Ductless Fume Hood

Advantages of a Ductless Fume Hood

Portable

Long Filter Life

Quiet Operation

Sturdy Construction

Low Maintenance

Simple Filter Change

Variety of Sizes

No Ductwork

No Makeup Air

Ductless Fume Hood Main Filter Choices

PARTICULATE FILTERS

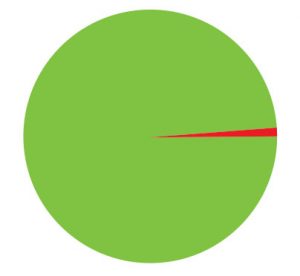

ULPA Filter

up to

99.9995%

Efficiency

down to

0.12 microns

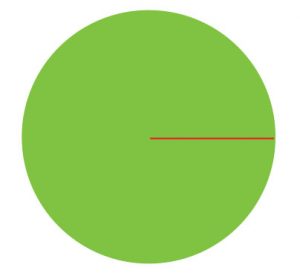

HEPA Filter

up to

99.97%

Efficiency

down to

0.3 microns

ASHRAE Filter

up to

95%

Efficiency

down to

0.5 microns

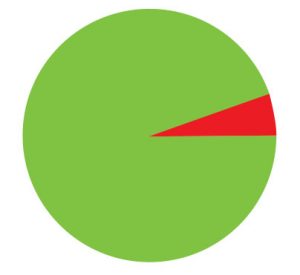

CHEMICAL FILTERS

Activated Carbon

Treated Carbon that has increased surface area in order to be more porous to adsorb chemical fumes.

Efficiency depends on chemical

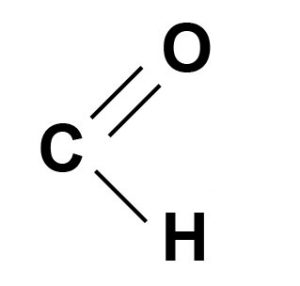

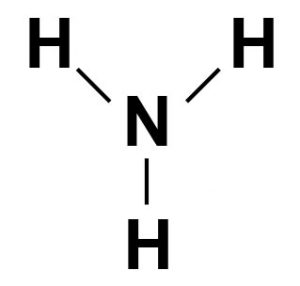

Specialty Blended

Acid Gas

Aldehyde

Ammonia

Mercury

Ductless Fume Hood Uses

3D Printing

Archaeology

Chemical Fumes

DNA

Forensic

Glasses Manufacturing

Mycology

Paints, Glues, Solvents

Pharmaceutical

Restoration of Art

Soldering

Stem Cells

Other Biological Applications or Processes Requiring Dust Removal

Made in the USA

Made in the USA