RuggedAir

The RuggedAir industrial fume extractor is designed to protect the operator’s breathing zone from harmful airborne fumes and particulate found in many industrial applications such as welding, metal working, and chemical and solvent control. Capable of providing up to 530 CFM of air volume, this system ensures pollutants are arrested at the source before they contaminate the larger work space.

This system is equipped with a cleanable Micro-Pleat Series 2 particulate filter that is cleaned by applying compressed air to the filter while still in the unit’s chassis. The operator simply sprays compressed air into the filter media to rejuvenate it while excess dust and waste falls into the internal dust pan, allowing for simple and clean debris removal. An alternative filter option include a 32lb. disposable activated carbon filter. The compact model 300 RuggedAir comes with a sturdy portability handle and four industrial grade locking casters, making moving this unit virtually effortless.

Model # SS-XXX-XXX

Unit Configurations Quick Compare

Additional Configurations

Features and Benefits

- Variable Speed Controller Included

- On/Off Buttons on inlet hood for convience

- LED Lighting on inlet hood

- Digtal Magnehelic Gage & Hour Counter

- Reliable, Low Maintenance Operation

- Heavy-Duty Casters & Portability Handles

- No Exterior Ducting Required

- Long Filter Life

- "No Tool" Filter Change

Available Filters

-

Round MERV 15 Micro-Pleat Series 2 Particulate Filter

-

HEPA Filter(Up to 99.97% efficient on particles down to 0.3 microns) Non-Cleanable

-

32lb Disposable Cartridge w/ Activated Carbon

200 Series

Product Video

Cabinet Dimensions:

- 30" diameter

- 27 " height, with plenum attached

Cabinet Material:

ABS Plastic & Aluminum

Arm Dimension:

- 7” Diameter, 7’ L Flexible, with 10.5" round inlet

Motor:

Fractional Horsepower

Total Weight:

Approx. 100 lbs.

Air Volume:

Variable Speed Control Standard | 530 CFM High

Electrical:

115/1/60, 2 amps

220/1/50, .75 amps

Sound Level:

Approximately 74 dba (High), 48 dba on (low). 3’ from inlet

Warranty:

Limited two-year warranty from date of shipment on defects due to materials or workmanship.

Patented Design:

Patent pending 13/463, 347

Product Video

Cabinet Dimensions:

- 30" diameter

- 27 " height, with plenum attached

Cabinet Material:

ABS Plastic & Aluminum

Hose Dimension:

- 6” Diameter, 12’ L Flexible

- 6” Diameter, 25’ Python Hose Available

Motor:

Fractional Horsepower

Total Weight:

Approx. 100 lbs.

Electrical:

115/1/60, 2 amps

220/1/50, .75 amps

Sound Level:

Approximately 74 dba (High), 48 dba on (low). 3’ from inlet

Warranty:

Limited two-year warranty from date of shipment on defects due to materials or workmanship.

Patented Design:

Patent pending 13/463, 347

Quick Compare

Standard

|

"Python" Hose

|

|

|---|---|---|

| Cabinet Dimensions: |

- 30" diameter - 27 " height, with plenum attached |

- 30" diameter - 27 " height, with plenum attached |

| Weight: | Approx. 100 lbs. | Approx. 100 lbs. |

| Electrical |

115/1/60, 2 amps 220/1/50, .75 amps |

115/1/60, .2 amps 220/1/50, .75 amps |

| Sound Level | Approximately 74 dba (High), 48 dba on (low). 3’ from inlet | Approximately 74 dba (High), 48 dba on (low). 3’ from inlet |

Accessories

SS-006-SR

Reduces sparks from

entering the unit.

Applications

- Welding

- Metal Fabrication

- Large Scale Factories

- Woodworking

- Sanding

- Grinding

- Automotive

- Buffing

- Refinishing

- Brazing

- Soldering

Resources

Filters

The Micro-Pleat Series 1 Particulate Filters are engineered to be easily cleaned with the use of pressurized air. This form of self-contained cleaning does not require removal of the filters; the operator simply sprays air into the filter media to clean and rejuvenate them while excess dust a nd waste falls into the internal dust pan, allowing for simple and clean debris removal. The included magnehelic gage is an excellent tool for determining filter saturation. Once the pressure levels begin to increase, the operator can clean the filters and the pressure reduction will be noted on the gage.

No self-cleaning components - Self-cleaning units often require a handful of parts that are required for the self-cleaning mechanism to work. These parts are often consumables as they tend to wear down and break which adds to the overall lifetime cost.

RuggedAir Benefit: With no self-cleaning components this unit will save thousands in potential lifetime costs.

Quick and quiet cleaning - The mechanism used in self-cleaning units often stores pressurized air then rapidly releases it onto the filter creating loud, distracting noises.

RuggedAir Benefit: Cleaning the filter only requires about 3-5 minutes and the air applied by the operator is relatively quiet when compared to traditional self-cleaning units.

Easy to access filter - Many self-cleaning units have the filter enclosed in a chassis which makes accessing the filter difficult and cumbersome.

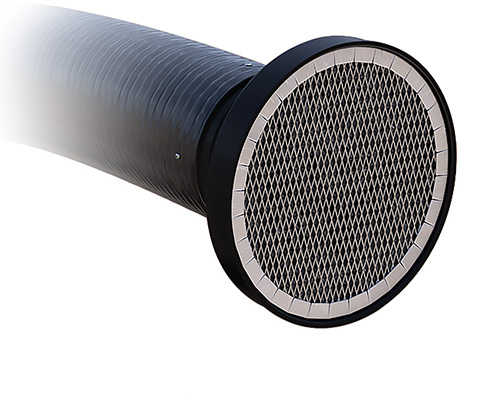

RuggedAir Benefit: The exposed filter design is protected by a mesh screen which makes accessing the filter to clean it virtually effortless.

Request A Quote or Contact Us

If you prefer, you may contact us by calling 800-799-4609, or e-mail us at sales@sentryair.com.

Name and Email are required.

Made in the USA

Made in the USA