Ambient Air Cleaner

Ambient Air Cleaners, manufactured by Sentry Air Systems, are low maintenance secondary engineering controls that pull contaminated air from the work area and re-circulate filtered air through a set of highly efficient air filters that remove harmful particles and particulate. These heavy-duty air cleaning units are used in large areas such as shops, warehouses and other highly populated areas that require secondary ambient air purification.

700 Series

Model # SS-XXX-XXX

Unit Configurations Quick Compare

Additional Configurations

What is an Ambient Air Cleaner?

An Ambient Air Cleaner is a commercial-grade air filtration system that is highly effective at removing ambient pollutants without the need for external ducting or make-up air. These low-maintenance filtration systems can be conveniently mounted in a desired ceiling location without taking any floor space, and in certain applications can be mounted on a stand. Typically used in locations where outside ventilation cannot suffice or may not be practical. Ambient air cleaners are utilized to aid in removing toxins, pollutants, and contaminants from the atmosphere.

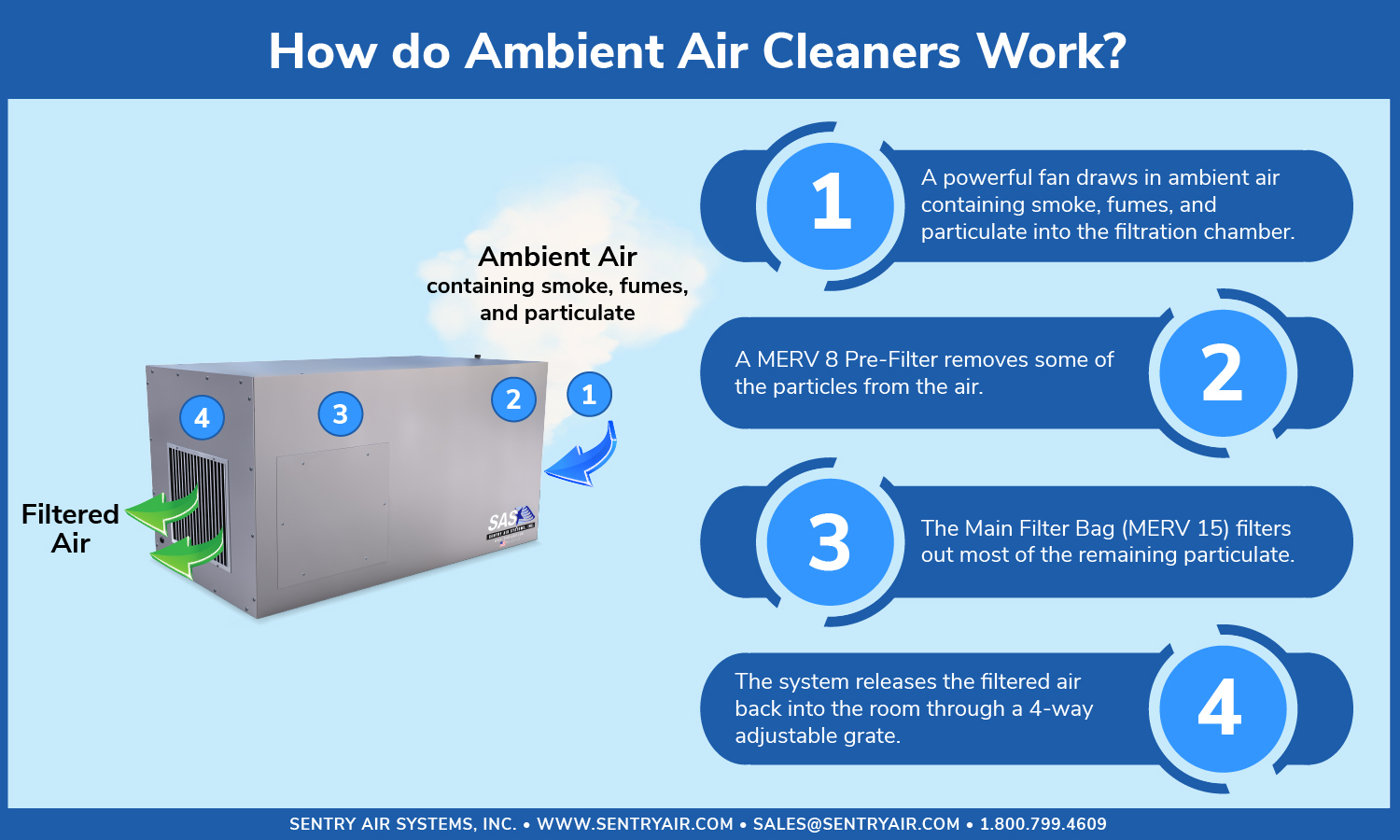

How does an Ambient Air Cleaner work?

Is your application appropriate for an Ambient Air Cleaner?

Sentry Air Systems ambient air filtration systems are designed and manufactured to accommodate a variety of applications making them the easiest industrial air cleaner to fit your specific needs. These air cleaners offer a modular solution in being able to be hung from a ceiling or mounted on a stand or wall.

There are many applications that fit the use of an Ambient Air Cleaner, typical uses include:

- Automotive Shops

- Welding

- Manufacturing Areas

- Woodshops

- Community Buildings

- Offices

- Cafeterias

- Sports Facilities

- Sanding

- Chemicals

- Grinding (Light)

- Solvent and Epoxy Fumes

- Dust

- Pharmaceutical

- Buffing

- Refinishing

- Brazing

- Commercial

Optional HEPA, ULPA, and charcoal filters are available for more demanding industrial ventilation system applications. However, in most cases, speaking with a subject matter expert to determine whether or not your application requires an ambient air cleaner is advisable.

Benefits of an Ambient Air Cleaner

- Multiple sizes and features are available

- Ductless and modular space-saving design

- Quiet operation

- Disposable filters for easy preservation

- Easy installation

- Energy and maintenance efficient

700 Series

Product Video

Cabinet Dimensions:

32 5/8"W x 24 3/4"D x 14.5"H

Cabinet Material:

16 ga. Carbon Steel, Powder Coated

Motor:

Fractional Horsepower 3/4

Total Weight:

132 - 160 lbs. (Varies depending on filter media installed)

Air Volume:

HEPA: Up to 600 CFM

ASHRAE: Up to 900 CFM

(2) ASHRAE: Up to 715 CFM

8lb. CARBON: Up to 800 CFM

16lb. CARBON: Up to 600 CFM

HEPA/8lb. CARBON: Up to 480 CFM

Electrical:

115/1/60, 4.9 amps

Sound Level:

Approx. 71dBA (High)

Warranty:

Limited two-year warranty from date of shipment on defects due to materials or workmanship.

Patented Design:

U.S. PATENT #5,843,197

Product Video

Cabinet Dimensions:

- 45"L x 24"W x 24"H

Cabinet Material:

- 16 ga. carbon steel w/ polyester epoxy coating on all surfaces

Air Volume:

Up to 2000 CFM

Motor:

Fractional Horsepower 3/4

Total Weight:

Approx. 115 lbs.

Electrical:

115/1/60, 8.7 amps

Sound Level:

66 to 70 dba (Blower Speed: Low to High) at 6'

Max Operating Temperature:

Not to exceed 170 degrees Fahrenheit

Warranty:

Limited two-year warranty from date of shipment on defects due to materials or workmanship.

Patented Design:

U.S. PATENT #5,843,197

Quick Compare

700 Series

|

2000 Series

|

|

|---|---|---|

| Cabinet Dimensions: | - 32 5/8"W x 24 3/4"D x 14.5"H | - 45"L x 24"W x 24"H |

| Weight: | 132 - 160 lbs. (Varies depending on filter media installed) | Approx. 115 lbs. |

| Electrical | 115/1/60, 4.9 amps | 115/1/60, 8.7 amps |

| Sound Level | Approx. 71dBA (High) | 66 to 70 dba (Blower Speed: Low to High) at 6' |

Accessories

Additional Configuration - Side Exhaust

SS-091-FES

7.5 ft height stand for elevated mounting.

Request A Quote or Contact Us

If you prefer, you may contact us by calling 800-799-4609, or e-mail us at sales@sentryair.com.

Name and Email are required.

Made in the USA

Made in the USA