Horizontal Laminar Flow Hood

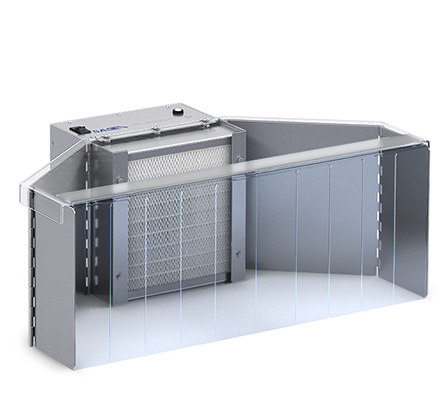

Horizontal laminar flow hoods, manufactured by Sentry Air Systems, are benchtop workstations that assist in providing a clean workspace by pushing a laminar stream of air through a HEPA filter into the working environment.

The unique design includes two “wing-style” sides that can adjust to make the work area either wider or more narrow. By utilizing a clear lid, operators have an additional layer of protection from ambient air; as a high-powered fan pulls the ambient air through the HEPA filter chamber - where airborne contaminants are captured then disperses the cleansed air into the work area.

Horizontal Laminar Flow Hood

Model # SS-XXX-XXX

Unit Configurations

What is a Horizontal Laminar Flow Hood?

Horizontal laminar flow hoods are anti-static clean room air filtration systems designed for stationary, benchtop applications requiring an ISO Class 5 rated environment. These flow hoods are unique in functionality as they pull ambient air through a HEPA filter, then disperse the clean air in a laminar flow through the designated work area.

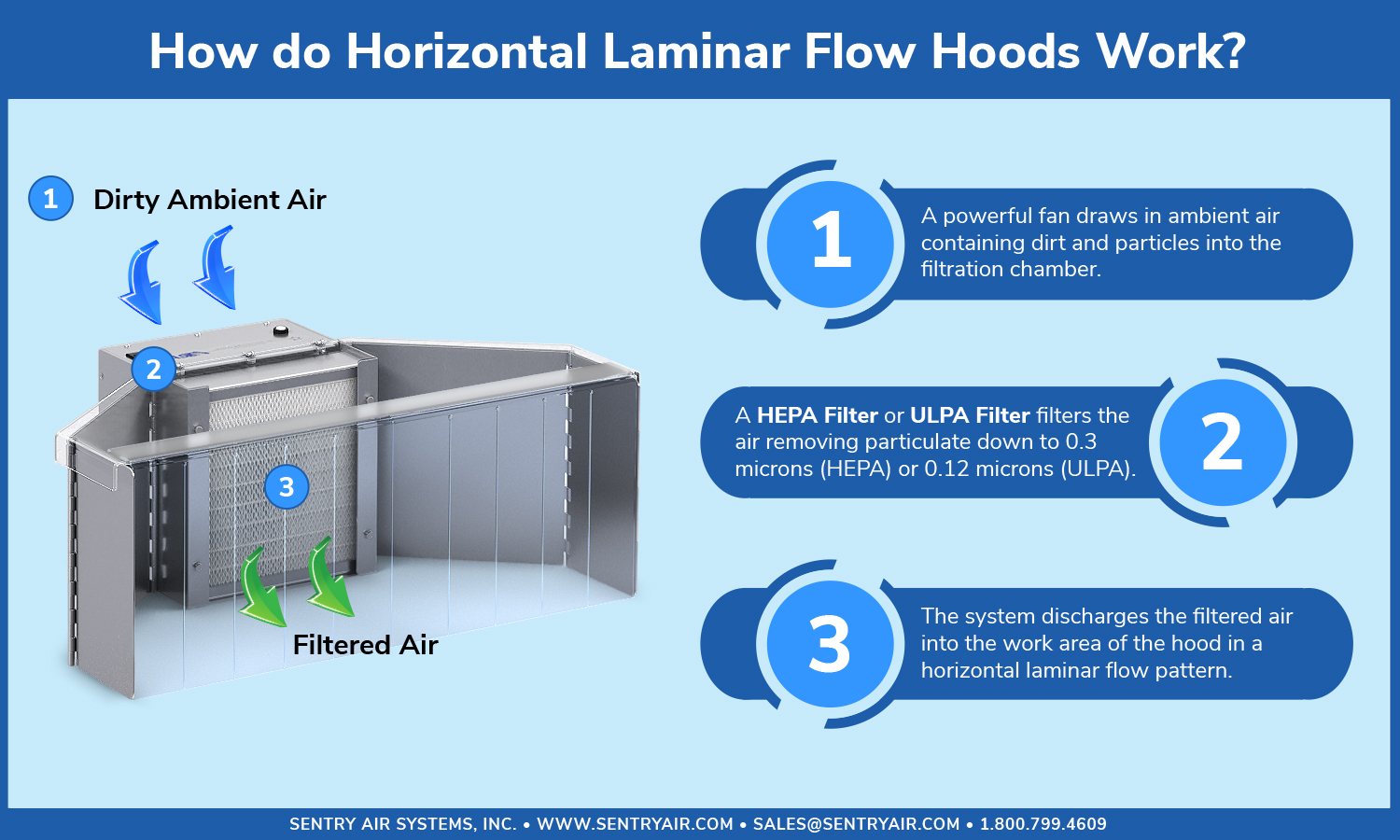

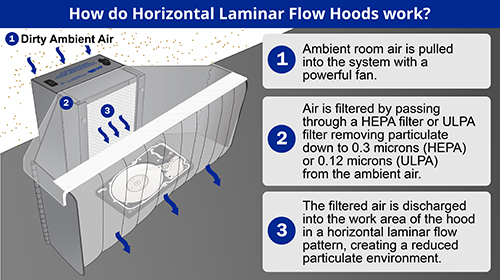

How does a Horizontal Laminar Flow Hood work?

Horizontal vs Vertical Laminar Flow Hood

Horizontal Laminar Flow Hoods:

- Ambient air is pulled from the back of the unit by a fan module

- The fan pushes the ambient air through HEPA (or ULPA) rated filters

- Filtered clean air is dispersed into enclosed work area of the hood in a horizontal laminar pattern

Vertical Laminar Flow Hoods (Cleanroom):

- Ambient air is pulled into the filtration system by a fan module

- (Air is processed through a MERV 8 pre filter) *SAS Additional Process

- The fan pushes the air through HEPA (or ULPA) rated filers

- Filtered air is discharged into the enclosed work area of the hood in a vertical laminar pattern

Is your application appropriate for a horizontal laminar fume hood?

Horizontal Laminar Flow Hoods are often required for pharmaceutical, medical, food and beverage manufacturing, tissue culture, electronics assembly and any other applications requiring an ISO Class 4 or 5 level of cleanliness. In some circumstances, important considerations must be taken, including what types of powders, chemicals, or biological mutagens will be handled, the quantity, and at what temperature. In these cases, speaking with a subject matter expert to determine whether or not your application requires a horizontal laminar flow hood is advisable.

Benefits of a SAS Horizontal Laminar Flow Hood

- Anti-Static

- Adjustable Wing Flaps

- Highly Portable and Lightweight

- Reliable, Quiet, Low Maintenance Operation

- Simple, Quick "No Tool" Filter Change

- Sturdy Construction

- Long Filter Life

- Clear Acrylic Lid and Curtains Included

200 Series

Product Video

Overall Dimensions:

6.25"L x 8"W x 8"H

Work Area Dimension:

21.25"W x 9"D

Motor:

Fractional Horsepower

Weight:

8 lbs.

Electrical:

115/1/60, .46 amps

Sound Level:

Approx. 66 dba @ 3'

Warranty:

Limited two-year warranty from date of shipment on defects due to materials or workmanship.

Patented Design:

U.S. PATENT #5,843,197

How do Horizontal Laminar Flow Hoods work?

Request A Quote or Contact Us

If you prefer, you may contact us by calling 800-799-4609, or e-mail us at sales@sentryair.com.

Name and Email are required.

Made in the USA

Made in the USA