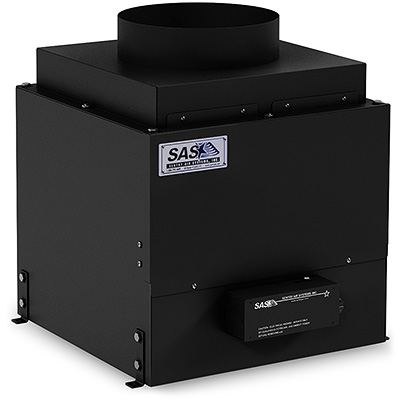

Mounted Fume Extractors

The mounted fume extractor is an incomparably manufactured air filtration system that is specifically built for work areas with minimal space allotted. Available to be mounted to shelves, tables, enclosures, machines, and other locations that require direct mounting, these units feature small footprints, allowing them to be easily integrated to work with existing equipment and workspace arrangements.

Mounted fume extractors are ductless and recirculate air through the use of powerful fans and high-quality filtration media. Filter media is selected depending on the application being performed and typically includes HEPA, ASHRAE, ULPA, Activated Carbon, or specialty-blended filter media [Acid Gas, Mercury, Aldehyde, Ammonia].

200 Series

Model # SS-XXX-XXX

Unit Configurations Quick Compare

Additional Configurations

Available Filters

-

HEPA FilterUp to 99.97% efficient on particles down to 0.3 microns

-

ASHRAE FilterUp to 95% efficient on particles down to 0.5 microns

-

ULPA FilterUp to 99.9995% efficient on particles down to 0.12 microns

- Activated Carbon & Specialty-Blended Filters

200 Series

Product Video

Chemicals SS-200

Cabinet Dimensions:

- 10.5"L x 10"W x 12.5"H

Cabinet Material:

- 16 ga. carbon steel

Motor:

Fractional Horsepower

Total Weight:

10 lbs.

Air Volume:

Up to 80 CFM

Electrical:

115/1/60, .3 amps

220/1/50, .2 amps

Sound Level:

Approx. 55 dba @ 3' from inlet

Max Operating Temperature:

Not to exceed 170 degrees Fahrenheit

Patented Design:

U.S. PATENT #5,843,197

Particulate SS-225

Cabinet Dimensions:

- 10.5"L x 10"W x 12.5"H

Cabinet Material:

- 16 ga. carbon steel

Motor:

Fractional Horsepower

Total Weight:

10 lbs.

Air Volume:

Up to 91 CFM

Electrical:

115/1/60, .46 amps

Sound Level:

Approx. 64 dba @ 3' from inlet

Max Operating Temperature:

Not to exceed 170 degrees Fahrenheit

Patented Design:

U.S. PATENT #5,843,197

Product Video

Cabinet Dimensions:

- 15.5"L x 13"W x 16.5"H

Cabinet Material:

- 16 ga. carbon steel

Motor:

Fractional Horsepower

Total Weight:

40-55 lbs.

Air Volume:

350 CFM High, Down to 25 CFM Low

Electrical:

115/1/60, 2 amps

220/1/50, .75 amps

Sound Level:

61 to 66 dba

Max Operating Temperature:

Not to exceed 170 degrees Fahrenheit

Warranty:

Limited two-year warranty from date of shipment on defects due to materials or workmanship.

Patented Design:

U.S. PATENT #5,843,197

Product Video

Chemicals SS-425

Cabinet Dimensions:

- 22.5"L x 20"W x 19.5"H

Cabinet Material:

- 16 ga. carbon steel

Motor:

Fractional Horsepower

Total Weight:

51 lbs to 100 lbs

Air Volume:

700 CFM High, Down to 50 CFM Low

Electrical:

115/1/60, 2.5 amps

220/1/50, 1.5 amps

Sound Level:

60 dba @ 3 ft. from hood inlet

Particulate SS-450

Cabinet Dimensions:

- 22.5"L x 20"W x 20"H

Cabinet Material:

- 16 ga. carbon steel

Motor:

1.5 HP

Air Volume:

Variable Speed Control Standard

733 CFM High, Down to 50 CFM Low

Electrical:

115/1/60, 5.2 amps

Sound Level:

72 dba @ 3 ft.

Max Operating Temperature:

Not to exceed 170 degrees Fahrenheit

Patented Design:

U.S. PATENT #5,843,197

U.S. PATENT #8,353,745

Quick Compare

200 Series

|

300 Series

|

400 Series

|

|

|---|---|---|---|

| Cabinet Dimensions: | 10.5"L x 10"W x 12.5"H | 15.5"L x 13"W x 16.5"H | 22.5"L x 20"W x 19.5"H |

| Weight: (lbs.) |

10 | 40-55 | 51 to 100 |

| Electrical |

115/1/60, .3 amps 220/1/50, .2 amps |

115/1/60, 2 amps 220/1/50, .75 amps |

400 Series: 115/1/60, 2.5 amps 220/1/50, 1.5 amps 450 Series: 115/1/60, 10.7 amps 220/1/50, 5.35 amps |

| Sound Level | Approx. 55 dba @ 3' from inlet | 61 to 66 dba | 60 dba @ 3 ft. from hood inlet |

Configurations

Applications

- Soldering

- Welding

- Chemicals

- Grinding (Light)

- Solvent and Epoxy Fumes

- Dust

- Pharmaceutical

- Buffing

- Refinishing

- Brazing

- Commercial

Request A Quote or Contact Us

If you prefer, you may contact us by calling 800-799-4609, or e-mail us at sales@sentryair.com.

Name and Email are required.

Made in the USA

Made in the USA