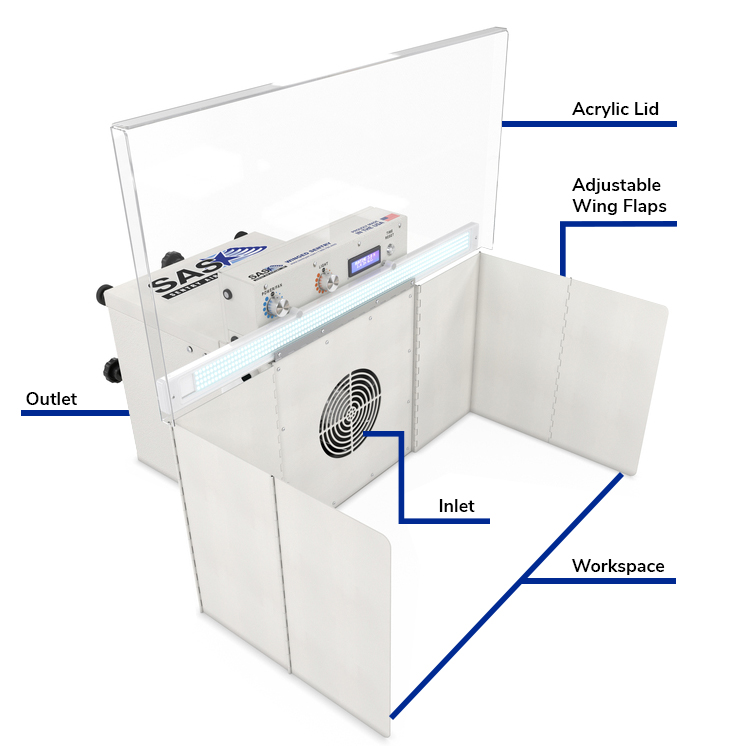

The Winged Sentry with Lid Generation 2 has a unique design with two adjustable wing flaps and an acrylic lid to aid in directing fumes and particulate into the filtration chamber.

Introducing the latest technology in benchtop fume extractors – the Model 300 Winged Sentry with Lid Generation 2 or WSL2. We’ve upgraded our Winged Sentry unit to add a user-friendly control panel to help make it easier to operate, monitor, and maintain the system. The WSL2 provides an economical fume control solution for space-constrained workplaces that can’t fit a traditional fume hood.

WSL2 Upgraded Features

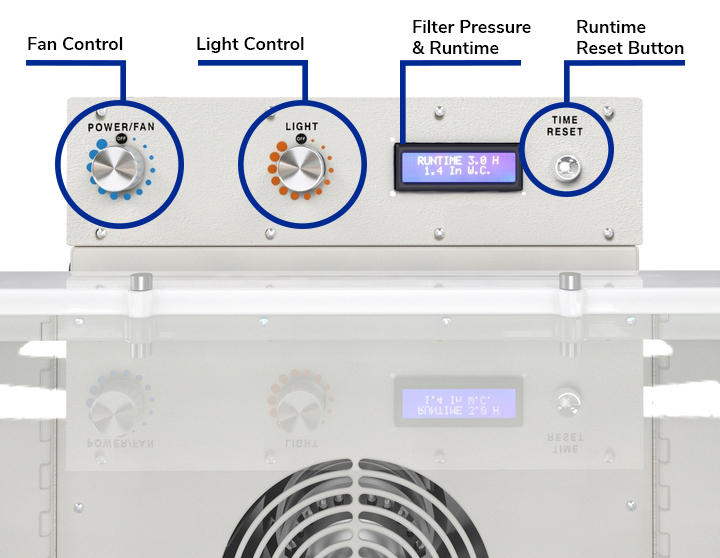

Close-up of the new WSL2’s user-friendly control panel with fan and light control knobs, digital display with filter pressure and runtime, and a runtime reset button.

WSL2 Standard Features

Standard features of the WSL2 that are available with the standard Model 300 WSL

WSL2 Applications

WSL2 provides an economical solution for various fume producing applications such as laboratory fume extraction.

• Chemical Fume Control

• Soldering

• Pharmaceutical Powder Filling & Pill Sorting

• Research & Development

• Using Solvents and Epoxies

• Laboratory Processes

• Other applications that produce fumes or airborne particulates

WSL2 Technical Specifications

| Work Area Dimensions | 14” depth x 28” wide x 13” height |

| Cabinet Material | 16 Ga. Carbon steel |

| Weight | 40 – 50 lbs |

| Air Volume | High: up to 350 CFM Low: down to 50 CFM |

| Electrical | 115/1/60, 2 amps 8’ grounded power cord with NEMA 5-15P plug |

| Sound Level | 54 to 66 dba |

| Main Filter Options | Depending on the Application: HEPA [up to 99.97% efficiency on particles 0.3 microns and larger] ASHRAE [up to 95% efficiency on particles 0.5 microns and larger] ULPA [up to 99.9995% efficiency on particles 0.12 microns and larger] Activated Carbon Specialty-Blended Filter Media [i.e. acid gas, aldehyde, and ammonia] |

Benefits of Sentry Air Systems

Sentry Air Systems manufactures all of our equipment at our facility located in Cypress, TX (a suburb of Houston).

• Low maintenance – only need to change the filter

• High-quality filters manufactured in-house

• Made in the USA

• 5 business days lead time for standard-size products

• Free chemical assessment for the best-suited filter for your application

• Expert support

Contact us today to learn more about the new WSL2 and how it can help your facility reduce workplace respiratory hazards.

Call us today – 1.800.799.4609

Related Blogs:

Engineering Controls to Reduce Exposure to Newly EPA-Banned Solvents TCE & PCE – https://www.sentryair.com/blog/industry-applications/chemical-solvents/engineering-controls-to-reduce-exposure-to-newly-epa-banned-solvents-tce-pce/

Deluxe Ductless Fume Hood (DCH2) Now UL-Certified https://www.sentryair.com/blog/company-news/deluxe-ductless-fume-hood-dch2-now-ul-certified/

Made in the USA

Made in the USA