The USP 797 IV Hood is designed to meet USP 797 guidelines and to help prevent cross contamination

of IV bags.

USP 797 defines proper sterile compounding procedures for compounded sterile preparations (CSPs) including injections, infusions, and IV bags. All applicable facilities must follow USP 797 guidelines to help preserve medication quality. USP 797 sterile compounding rules apply to “hospitals, other healthcare facilities, patient treatment sites, infusion facilities, pharmacies, and physicians/veterinarians practice sites” (USP 2022). Infusion clinics and mobile IV clinics must follow USP 797 guidelines to ensure patient safety.

What is USP 797?

USP 797 defines the best practices for sterile compounding, including IV bag infusion or preparing IV bags in advance for future use. The purpose of USP 797 is to “minimize harm, including death, to human and animal patients” (USP 2022). USP 797 defines the proper methods to minimize contamination and maintain sterility including the following subjects (USP 2022):

Personnel Qualifications

Personal Hygiene and Garbing

Facilities and Engineering Controls

Microbiological Air and Surface Monitoring

Cleaning and Disinfecting

Equipment, Supplies, and Components

Sterilization Methods

Record Keeping

Release Testing

Labeling

Establishing Beyond-Use Dates

Quality Control

Storage, Handling, Packaging, Shipping, and Transport

Documentation

USP does not enforce these regulations only mandates — local regulatory jurisdictions will ensure compliance for applicable facilities.

What is sterile compounding?

USP defines sterile compounding as “combining, admixing, diluting, pooling, reconstituting, repackaging, or otherwise altering a drug or bulk drug substance to create a sterile medication” (USP 2022).

Engineering Controls for USP 797

For sterile compounding of IV infusions or IV bags, USP 797 requires the primary engineering control (PEC) to be certified to meet ISO Class 5 or better, designed to prevent contamination of CSPs, and must maintain a unidirectional airflow. One of the approved types of PECs is a laminar airflow system (LAS) or laminar airflow bench (LAFW).

What is a Laminar Airflow Workbench (LAFW)?

A laminar airflow workbench is an enclosed workspace that is supplied with HEPA filtered air in a unidirectional airflow. To meet USP 797, a laminar airflow workbench must provide ISO Class 5 air or better, have horizontal or vertical unidirectional airflow, and utilize HEPA filters (USP 2022). This type of PEC does have certain limitations, as it can’t be used for the preparation of antineoplastic or active pharmaceutical ingredients.

Placement of a Laminar Airflow Workbench

The placement of a laminar airflow workbench used for sterile compounding depends on the type of compounded sterile preparation (CSP). For all category 1 CSPs, LAFWs can be utilized in an unclassified segregated compounding area (SCA). The SCA must be used only for compounding, be free from clutter, and be easy to keep clean and disinfected. Also, the SCA must be placed away from strong air currents from opening doors and windows, strong HVAC air streams that may interrupt the unidirectional airflow, and any airflow caused from personnel traffic. USP 797 recommends that the SCA have smooth surfaces with no cracks or crevices, be cleaning chemical resistant, and minimize areas where dust can collect, such as overhangs (USP 2022).

For category 2 and 3 CSPs, facilities must place an LAFW in an ISO Class 7 buffer room with more than 30 air changes per hour (ACPH) and have an ISO Class 8 ante room with more than 20 ACPH. Please refer to USP 797 for more detailed information about requirements for category 2 and 3 CSPs.

USP 797 Certification and Recertification for LAFW

Both USP 797 and CETA’s CAG 003 detail the required testing for PEC or LAFW certification and recertification. CETA, Controlled Environment Testing Association, defines CAG 003, the industry standard for certifying sterile compounding facilities, and details the specialized testing procedures for UPS 797 certification of PEC (CETA 2022). Certification must be conducted by an independent 3rd party and recertified every 6 months. Other conditions that require recertification are after a HEPA filter change or if the LAFW is moved to a different location. Listed below are the extensive tests for PEC certification under USP 797 and CAG 003 (USP 2022 & CETA 2022).

Airflow Test

Tests the air velocity and air changes per hour to verify that it matches the manufacturer’s specifications and required USP 797 levels.

HEPA Filter Integrity Test

The HEPA filter must be leak tested at the factory, after installation, and during recertification.

Total Particle Count Test

Using a particle counter, the PEC must meet the maximum allowed number of particles for ISO Class 5, which is 10,200 for particles ≥ 0.3 microns and 3,520 for particles ≥ 0.5 microns.

Dynamic Airflow/Smoke Pattern Test

Ensures proper airflow direction, patterns, and uniformity to identify potential disruptions or turbulence that could compromise the integrity of the workspace.

Induction Leak Testing

Ensures the system meets ISO Class 5 standards and adequately isolates the direct compounding area.

Backstreaming Testing

Test to ensure the ambient air doesn’t enter the workspace.

For more detailed information on the testing protocol, please refer to CETA’s CAG 003 documentation.

Sentry Air Systems Solutions for USP 797

The USP 797 IV Hood has been stringently tested in-house and certified by a 3rd party to meet USP 797.

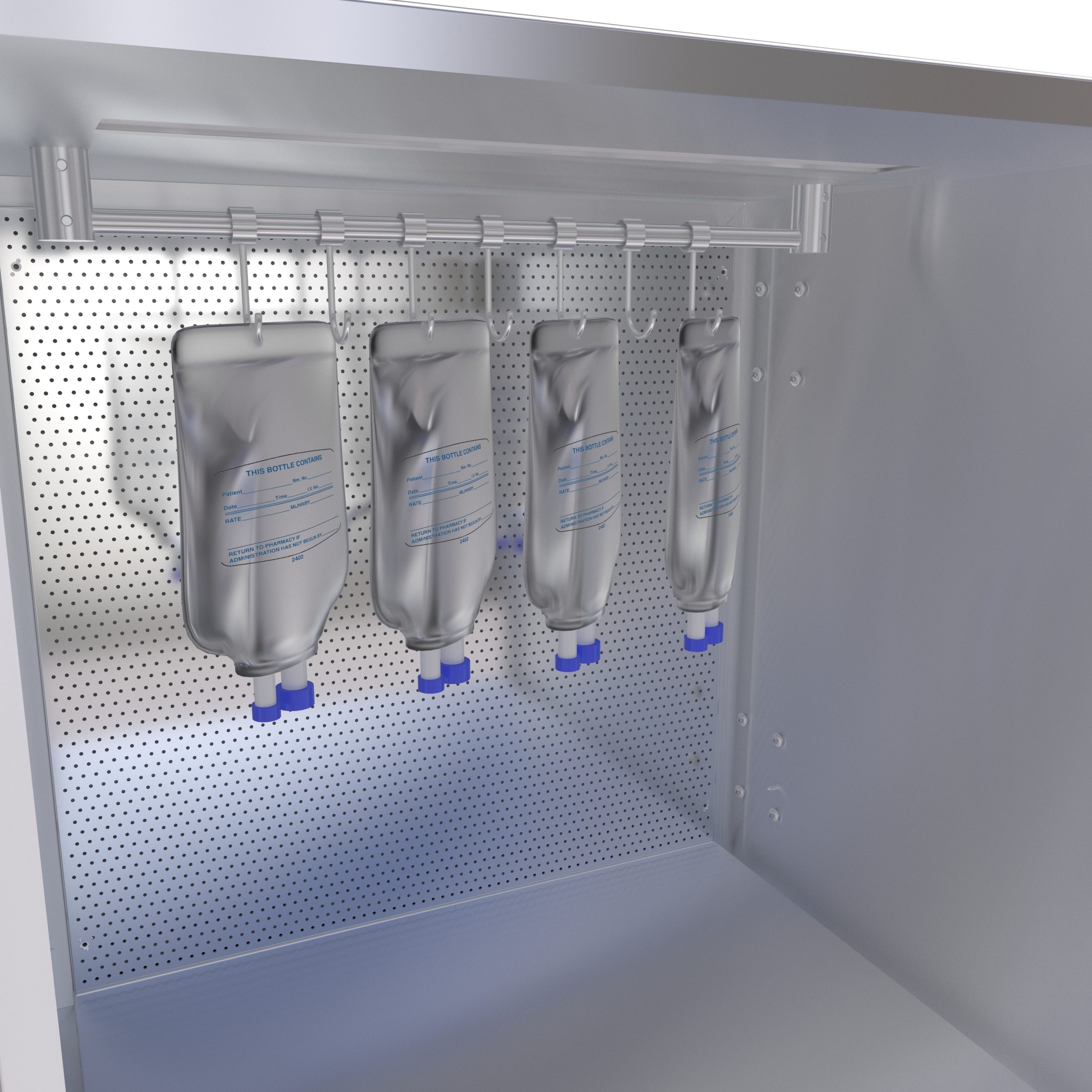

The USP 797 IV Hood includes a 7-hook IV storage rod.

• ISO Class 5 Cleanroom and USP 797 Certified (copy of test protocol available upon request)

• Designed to Prevent Contamination of IV Bags

• Horizontal Unidirectional Airflow

• Leakproof Design

• Quiet and Energy-Efficient EC Motor

• Quick Lead Time – Average of 5 days or less. (Expedite service available for additional fee)

• Made in the USA

• 7-hook IV Bag Storage Rod Storage (shown right)

The USP 797 IV Hood features an easy to use control panel with fan/light controls and a Magnehelic gauge .

Another benefit of the USP 797 IV Hood is the easy-to-use control panel featuring: adjustable LED light, fan speed control, and a Magnehelic Gauge to monitor the filter’s static pressure/filter saturation.

Filter: HEPA (up to 99.97% efficiency on particles down to 0.3 microns)

Dimensions (Depth x Width x Height”:

Outer: 25″ x 19.5″ x 21.75″

Interior: 15.5″ x 17″ x 17″

Access Area: 17″ x 17″

Approximate Airflow: up to 418 CFM with HEPA filter

Light Intensity: 1800 LUX at work surface

Help preserve patient safety and medication quality by preparing IV bags in a Laminar Airflow Workbench designed to meet USP 797.

Contact us today to get started! Call us at 1-800-799-4609

Related Blogs

• Proper IV Bag and Medication Preparation Can Help Save Lives

• Best Practices for Spiking of IV Bags

References

CETA. (Oct 2022). CETA Application Guide CAG-003: Certification of Sterile Compounding Facilities for USP Compliance. Retrieved from: https://www.cetainternational.org/ceta-application-guides-for-nonmembers-

USP. (2022). <797> Pharmaceutical Compounding – Sterile Preparations. Retrieved from: https://www.usp.org/compounding/general-chapter-797

Made in the USA

Made in the USA