An employee operating coffee roasting equipment at a coffee production facility. (Source)

During coffee production of both flavored and unflavored coffee, production employees become exposed to dangerous VOCs resulting in irreversible lung damage (Ref. 1). The most hazardous VOCs released from flavorings and naturally from roasting coffee beans are diacetyl and 2,3-pentanedione. Exposure to even small amounts over time or large concentrations over a short period of time can have drastic health effects (Ref. 2). Coffee production facilities need to be aware of the hazards and implement exposure reduction procedures to protect employee health and safety.

What is Diacetyl and 2,3-pentanedione?

Diacetyl and 2,3- pentanedione are classified as alpha-diketones and can be found as an ingredient in microwave popcorn, baking mixes, and flavored coffee (Ref. 1). NIOSH found that out of 26 bulk flavorings that 21 had diacetyl and 15 had 2,3-pentanedione (Ref. 3). Many of the flavorings safety data sheets did not include diacetyl and 2,3-pentanedione as an ingredient, instead listed it as a proprietary ingredient (Ref. 3). However, in some cases, the manufacturer produced a diacetyl-free flavoring but acetoin, a common flavoring ingredient, released diacetyl as a natural by-product (Ref. 3). As a substitute for diacetyl, many flavoring manufacturers use 2,3-pentanedione without realizing the similarity to diacetyl chemical properties and hazardous side effects (Ref. 4).

Until recently, manufacturers thought that exposure to diacetyl only occurred during flavored coffee production (Ref. 1). However, recent studies have found that roasting coffee beans naturally release VOCs, including both compounds, from the chemical reaction between the beans’ sugars and amino acids (Ref. 5). Fermentation processes naturally create diacetyl in products such as yogurt, beer, and butter (Ref. 2). The FDA advises that diacetyl is safe to consume in small amounts, but research shows that inhalation of diacetyl can result in lasting health effects (Ref. 2).

Exposure during Coffee Production

Exposure to diacetyl and 2,3-pentanedione occurs mainly during roasting, opening storage bins, grinding, packaging, adding flavors to coffee beans, and in quality control testing rooms (Ref. 6). As coffee roasts, the beans release VOCs including diacetyl, 2,3-pentanedione, and other less harmful chemicals along with carbon dioxide and carbon monoxide (Ref. 7). The concentration and exact VOCs released during roasting depend on the roasting temperature, the duration, the coffee bean variety, and the grinding process (Ref. 7). After roasting, production stores the beans in bins or hoppers for cooling and “off-gassing” causing a buildup of chemicals (Ref. 8). Upon opening of bins, this buildup results in high concentration exposure of alpha-diketones to the employee (Ref. 8). When employees grind roasted coffee beans, the surface area increases allowing for greater “off-gassing” of diacetyl and 2,3-pentanedione (Ref. 1). In some facilities, production packages recently roasted coffee in permeable bags to allow off-gassing while in the packages, in turn exposing packaging employees to these fumes (Ref. 1). Similarly, when employees add flavorings to coffee such as hazelnut, diacetyl and 2,3-pentanedione become dispersed in the air. This release occurs because the flavorings either directly have the chemicals as an ingredient or due to a natural by-product of acetoin (Ref. 3). In quality control and testing rooms, employees roast and grind small amounts of beans to check for quality, flavor profile, and consistency (Ref. 2). The repeated roasting and grinding of beans in a small confined area exposes employees to these fumes.

Due to the chemically similar nature of diacetyl and 2,3-pentanedione scientists consider exposure to be an “additive mixture formula” which means exposure should be measured or considered in combined levels (Ref. 5). Ideally, employers should minimize exposure to combined levels below the National Institute of Occupational Safety & Health (NIOSH) recommended exposure limit (REL).

Coffee Production Exposure Testing

NIOSH conducted exposure evaluations at numerous coffee production facilities.

Approximately 658 coffee production establishments with 20,000 people employed nationwide may become exposed to diacetyl and 2,3-pentanedione on a daily basis (Ref. 5). Several facilities had employees develop severe lung conditions after as little as 18 months, prompting other facilities to question respiratory safety in coffee production. Coffee production companies around the country decided to invite NIOSH to test exposure levels to safeguard employee health. Exposure readings varied depending on whether the facility made flavored or unflavored coffee, the task being performed, and whether or not the facility had any ventilation or airflow exchange.

Flavored Coffee Production

In flavored coffee production facilities, the highest average exposure rates occurred in the flavoring, grinding, and packaging areas (Ref. 1 & 4).

In an exposure evaluation conducted by NIOSH of a flavored coffee production plant, management sectioned off the flavoring area through a negative pressure environment to protect the unflavored coffee from contamination (Ref. 4). Even under negative pressure, the flavoring room had very high levels of both fumes on personal and air samples (Ref. 4). On the other hand, the unflavored production area exposed nearby production offices to the fumes, due to the lack of separation and fume control. This resulted in the production offices exhibiting high exposure of diacetyl and 2,3-pentanedione above the NIOSH REL of 5 ppb for diacetyl and 9.3 ppb for 2,3-pentanedione. The chart below summarizes the highest diacetyl and 2,3-pentanedione personal and air readings for the facility (Ref. 4).

Sample Readings by Production Area in a Flavored Coffee Production Facility (Ref. 4)

| Chemical | Area | Air Sample (parts per billion) |

Personal Sample (parts per billion) |

| Diacetyl | Grinding/Packaging | 102.8 ppb | 93 ppb |

| Flavoring | 90.3 ppb | 79.6 ppb | |

| Production Offices | 61.4 ppb | 77.3 ppb | |

| 2,3-pentanedione | Grinding/Packaging | 103.4 ppb | 86.1 ppb |

| Flavoring | 178.5 ppb | 143.1 ppb | |

| Production Offices | 62.2 ppb | 54.1 ppb | |

| Outside Flavoring Room Exhaust | 99.5 ppb | n/a |

In a similar exposure evaluation conducted by NIOSH, another flavored coffee production facility had high exposure concentrations in the flavoring, grinding, and packaging areas (Ref. 1). However, this facility utilized a downdraft ventilation unit by the roaster to decrease exposure to employees. This system helped reduce exposure rates immensely but did not remove fumes enough to meet NIOSH’s REL of 5 ppb for diacetyl and 9.3 ppb for 2,3-pentanedione (Ref. 1). Due to the low exposure limit of diacetyl and 2,3-pentanedione, this facility needs to add more protection to ensure respiratory safety in the roasting room (Ref. 1). Also, other production areas such as the flavoring, grinding, and packaging had no ventilation or fume control solution. These areas produced high concentrations of exposure and need fume control solutions. This chart below depicts the minimum and maximum personal readings that were still above NIOSH’s recommended exposure limits for both substances.

in a Flavored Coffee Production Facility (Ref. 1)

| Chemical | Production Task | Minimum Concentration (parts per billion) |

Maximum Concentration (parts per billion) |

| Diacetyl | Flavor Coffee | 22.7 ppb | 67.2 ppb |

| Grind Coffee Beans | 11.9 ppb | 32.0 ppb | |

| Move Roasted Coffee | 13.3 ppb | 13.3 ppb | |

| Package Coffee | 23.0 ppb | 53.2 ppb | |

| Roast Coffee Beans | 5.8 ppb | 15.9 ppb | |

| 2,3-pentanedione | Flavor Coffee | 24.2 ppb | 82.6 ppb |

| Grind Coffee Beans | 18.3 ppb | 36.4 ppb | |

| Move Roasted Coffee | 13.7 ppb | 13.7 ppb | |

| Package Coffee | 29.0 ppb | 56.8 ppb | |

| Roast Coffee Beans | 4.6 ppb | 19.0 ppb |

Unflavored Coffee Production

In unflavored coffee production plants, roasting, grinding, and packaging had the highest concentrations of diacetyl and 2,3-pentanedione (Ref. 9 & 10).

In a NIOSH conducted exposure evaluation, an unflavored coffee production facility had no ventilation illustrating the exposure rates for roasting, packaging, and grinding with no airflow exchange (Ref. 9). For diacetyl, the roasting, grinding, storage, and general production areas had the highest exposure rates. Because of the lack of separation between the bakery, café, and production areas, coffee fumes spread to customer areas resulting in high exposure concentrations above the NIOSH REL of 5 ppb. But, the NIOSH REL only pertains to workplace exposure over an 8 hour period in a 40 hour work week, thus the high exposure numbers are not regarded as a health risk for customers. For 2,3-pentanedione, storage, roasting, and grinding areas had the highest exposure concentrations but the production area, production office, quality control lab, and packaging areas also had concentrations over the NIOSH REL of 9.3 ppb. See the chart below for a summary of the diacetyl and 2,3-pentanedione exposure of both personal and air samples sorted by area in the plant.

Different Areas of an Unflavored Coffee Production Facility (Ref. 9)

| Personal Samples |

Air Samples | ||||

| Chemical | Location | Minimum Concentration (parts per billion) |

Maximum Concentration (parts per billion) |

Minimum Concentration (parts per billion) |

Maximum Concentration (parts per billion) |

| Diacetyl | Bakery | 7.7 ppb | 8.5 ppb | 6.3 ppb | 6.8 ppb |

| Production Area | 12.8 ppb | 40.5 ppb | — | — | |

| Production Office | 7.4 ppb | 30.4 ppb | — | — | |

| Quality Control Lab | 7.5 ppb | 12.7 ppb | 6.4 ppb | 11.7 ppb | |

| Roasting | 19.5 ppb | 34.7 ppb | 20.8 ppb | 36.2 ppb | |

| Grinding | — | — | 19.5 ppb | 28.6 ppb | |

| Roasted Bean Storage | — | — | 19.3 ppb | 41.3 ppb | |

| Packaging | — | — | 10.7 ppb | 61.2 ppb | |

| 2,3-pentanedione | Bakery | 4.8 ppb | 5.8 ppb | 4.5 ppb | 4.7 ppb |

| Production Area | 10.4 ppb | 27.1 ppb | — | — | |

| Production Office | 6.9 ppb | 21.2 ppb | — | — | |

| Quality Control Lab | 5.4 ppb | 10.1 ppb | 5.6 ppb | 8.9 ppb | |

| Roasting | 16.6 ppb | 25.1 ppb | 17.6 ppb | 29.3 ppb | |

| Grinding | — | — | 15.4 ppb | 20.6 ppb | |

| Roasted Bean Storage | — | — | 17.2 ppb | 28.4 ppb | |

| Packaging | — | — | 9.4 ppb | 38.0 ppb | |

This study also tested the short term exposure in the unflavored coffee production plant. Diacetyl and 2,3-pentanedione can be very dangerous if high concentrations exposure occurs in a short amount of time (15 minutes) and must be monitored to minimize serious health risks. NIOSH recommends limiting the short term exposure of diacetyl and 2,3-pentanedione to 25 ppb and 31 ppb respectively. Grinding, packaging, roasting, and while cleaning the roaster gave the highest short term exposure concentrations of diacetyl and 2,3-pentanedione. The chart below showcases the highest short term exposure rates in this facility (Ref. 9).

in an Unflavored Coffee Production Facility (Ref. 9)

| Chemical | Task | Minimum Concentration (parts per billion) |

Maximum Concentration (parts per billion) |

| Diacetyl | Cleaning Roaster | 11.3 ppb | 28.7 ppb |

| Grinding | 53.2 ppb | 66.9 ppb | |

| Packaging | 14.0 ppb | 56.0 ppb | |

| Roasting | 7.2 ppb | 25.6 ppb | |

| 2,3-pentanedione | Cleaning Roaster | 8.4 ppb | 18.1 ppb |

| Grinding | 32.3 ppb | 53.8 ppb | |

| Packaging | 12.1 ppb | 46.6 ppb | |

| Roasting | 7.1 ppb | 25.1 ppb |

In a different NIOSH exposure evaluation study for an unflavored coffee production facility, over the recommended limit exposure occurred mainly in the grinding and packaging areas even though the facility had a rooftop air handling unit that mitigated exposure (Ref. 10). Even with some form of ventilation, grinding and packaging in unflavored coffee production requires additional fume extraction to maintain exposure rates below the NIOSH REL levels (diacetyl – 5 ppb, 2,3-pentanedione – 9.3 ppb). The chart below illustrates the readings captured in this study that were above NIOSH REL levels.

Unflavored Coffee Production Facility (Ref. 10)

| Chemical | Task | Minimum Concentration (parts per billion) |

Maximum Concentration (parts per billion) |

| Diacetyl | Grinding | 14.8 ppb | 31.8 ppb |

| Packaging | 4.0 ppb | 11.7 ppb | |

| 2,3-pentanedione | Grinding | 7.7 ppb | 19.5 ppb |

Diacetyl and 2,3-pentanedione Exposure Health Risks

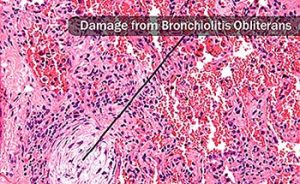

Lung with damage from Bronchiolitis Obliterans (Source)

Overexposure of diacetyl and 2,3-pentanedione can result in lifelong lung damage. In Texas, five employees at a flavored coffee production facility developed bronchiolitis obliterans from diacetyl exposure. This condition developed after about 18 months of exposure and resulted in one previously healthy 35-year-old woman needing a lung transplant (Ref. 2). Bronchiolitis obliterans cause inflammation and damages the bronchioles, the tiniest airways in the lungs. After damage, scar tissue forms, further restricting the airways resulting in irreversible lung damage (Ref. 11). Bronchiolitis obliterans can never be reserved and severely limits lung function by as much as 76% (Ref. 2). Physicians find this condition difficult to diagnose because the symptoms are similar to those of asthma or chronic pulmonary disease. Often once it is diagnosed, it is too late. Symptoms of bronchiolitis obliterans include shortness of breath, dry cough, irregular fatigue, black mucus, and wheezing with symptoms not improving over time off or weekends (Ref. 5). This condition develops rapidly resulting in lung damage in months instead of years or decades (Ref. 5).

Moreover, diacetyl and 2,3-pentanedione can cause occupational asthma (Ref. 6). Exposure can aggravate eye, nose and sinus symptoms. Employees can become sensitized to exposure and develop immune reactions to even low concentrations of exposure (Ref. 6).

In other industries, overexposure to diacetyl resulted in five deaths in popcorn factories (Ref. 11). Animal studies back up these devastating effects with rats suffering significant lung damage after being exposed to diacetyl. In one federal study conducted in 2001, scientists exposed rats to similar levels as the employees at the popcorn facilities, resulting in half of the rats dying within six hours and the rest exhibiting major lung injuries (Ref. 11).

Diacetyl and 2,3-pentanedione Standards

Due to the incidents with devastating health effects, National Institute for Occupational Safety and Health (NIOSH) and American Conference of Governmental Industrial Hygienists (ACGIH) created recommended exposure limits for both 8-hour shifts and 15-minute short term exposure of diacetyl and 2,3-pentanedione (Ref. 12). The chart below depicts the current standards by NIOSH and ACGIH.

| Organization | Type | Diacetyl (parts per billion) |

2,3-pentanedione (parts per billion) |

| NIOSH | Recommended Exposure Limit (8 hours/day, 40 hours/week) |

5 ppb | 9.3 ppb |

| Short Term Exposure Limit | 25 ppb | 31 ppb | |

| ACGIH | Threshold Limit Value (8 hours/day, 40 hours/week) |

10 ppb | None |

| Short Term Exposure Limit | 20 ppb | None | |

| OSHA | |||

Currently, OSHA does not have a standard for diacetyl and 2,3-pentanedione or enforce restricting exposure (Ref. 11). In 2009, OSHA created a draft for exposure limits estimating that there are 4,000 diacetyl and 2,3-pentanedione related lung diseases cases a year and a permissible exposure limit (PEL) would save $2.3 billion annually, as cases usually end up leading to the employee receiving disability benefits (Ref. 11). However, OSHA did not finalize the standard and instead issued a health safety bulletin about diacetyl and 2,3-pentanedione. OSHA promised to continue to study the health effects of diacetyl exposure and in 2011 OSHA created programs to bring attention to the risks, increased inspections of facilities using diacetyl, and offered support to companies looking to increase worker safety (Ref. 11). Although there is no legal standard, diacetyl and 2,3-pentanedione exposure could fall under the OSHA regulation requiring employees to free the workplace from all “recognized hazards that are causing or likely to cause death or serious physical harm” (Ref. 2). Employers should conduct their own air monitoring and medical surveillance to ensure employee respiratory protection.

Diacetyl and 2,3-pentanedione Exposure Prevention

To minimize exposure to diacetyl and 2,3-pentanedione, NIOSH recommends that employers take action to protect employees. NIOSH offers the following suggestions on how to reduce exposure:

• Create and implement a respiratory protection plan (Ref. 5).

• Use engineering controls such as fume extractors and/or local exhaust ventilation system by the grinders, roasting ovens, and other areas of high exposure (Ref. 2).

• Offer employees respirators to wear (Ref. 8).

• Utilize appropriate heating and cooling ventilation system to supply new or filtered air to the facility (Ref. 2).

• Monitor air concentrations by testing air every 6 months (Ref. 8).

• Conduct medical monitoring every 6 months to identify worsening symptoms (Ref. 2).

• Use production best practices such as keeping face away from bins, keeping flavor containers closed when not in use, isolating high exposure areas, enclosing grinders and packaging machines, etc. (Ref. 3).

Sentry Air Solutions for Coffee Production Facilities

From the NIOSH exposure evaluations, the results showed that even in some facilities with coverings and ventilation systems unsafe levels of diacetyl and 2,3-pentanedione persisted during flavoring, checking on roasting beans, and working on equipment. All facilities should consider implementing added protection for fume control to protect employee respiratory safety. Facilities without any protection especially need to familiarize with exposure prevention engineering controls.

At Sentry Air Solutions, we offer a variety of solutions to protect employees’ health in coffee production plants. Air exchanges or outside exhaust systems can be a costly investment as well as wasting valuable temperature controlled air. Sentry Air Systems fume extractors do not require ductwork or makeup air providing a more economical fume control solution.

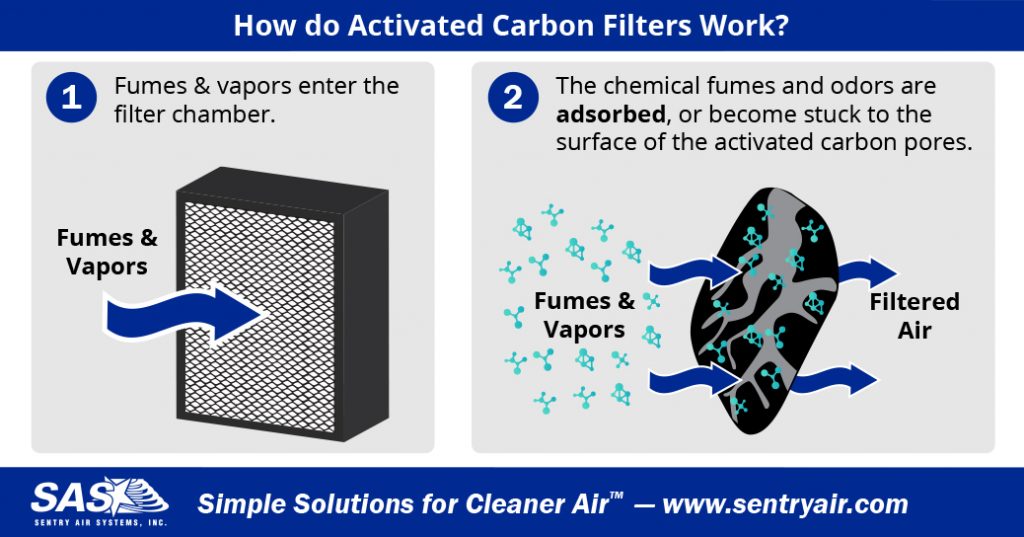

For chemical fumes like diacetyl and 2,3-pentanedione, we recommend utilizing activated carbon filters. Activated carbon filters are treated to increase the surface area to improve the adsorption of the chemical to the carbon’s surface. Adsorption varies from absorption as the chemical sticks to the surface rather than being contained in the substance. The picture below illustrates how activated carbon filters work.

Our activated carbon filters are made from crushed virgin coconut shells to provide optimized efficiency. Filter efficiency varies by chemical and application. Many of our systems offer dual main filter chambers allowing the system to not only remove fumes but capture particulate with high-efficiency particulate filters. Capturing particulate would allow facilities to minimize respirable coffee dust in addition to controlling coffee production fumes.

Portable Fume Extractor – SS-300-PFS

Portable Air Cleaner – SS-300-PRAC

Industrial Ambient Air Filtration System – SS-700-FH

Protect employee safety in flavored and unflavored coffee production with fume extractors and ambient air filtration systems!

Call us today at 1-800-799-4609

Sources

1. Fechter-Leggett, E. D., Grant, M. P., Johnson, A. R., & Martin Jr., S. B.. (2018, April). Evaluation of Exposures and Respiratory Health at a Coffee Roasting and Flavoring Facility. NIOSH Health Hazard Evaluation Report # 2017-0020-3316. Retrieved from: https://www.cdc.gov/niosh/hhe/reports/pdfs/2017-0020-3316.pdf

2. Rutledge, Raquel. (2018, November). Surprised by Dangerous Fumes in Coffee Roastery and Café, Stone Creek takes Steps to Protect Employees. Milwaukee Journal Sentinel. Retrieved from: https://www.jsonline.com/story/news/investigations/2018/11/21/coffee-shop-chemicals-stone-creek-takes-steps-protect-employees/2053324002/

3. (2019, April). NIOSH: Food processing workers exposed to hazardous flavoring chemicals. Safety.BLR. Retrieved from: https://safety.blr.com/workplace-safety-news/hazardous-substances-and-materials/chemical-hazards/NIOSH-Food-processing-workers-exposed-to-hazardous/

4. Bailey, R. L., Cox-Ganser, J. M., Duling, M. G., Kreiss, K., LeBouf, R. F., & Martin Jr., S. B. (2016, October). Environmental Characterization of a Coffee Processing Workplace with Obliterative Bronchiolitis in Former Workers. Journal of Occupational and Environmental Hygiene. Retrieved from: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5836548/

5. Rutledge, Raquel. (2015, June). Coffee Roasters’ Health at Risk from Chemical Compound, Air Samples Suggest. Milwaukee Journal Sentinel. Retrieved from: http://archive.jsonline.com/watchdog/watchdogreports/coffee-roasters-health-at-risk-from-chemical-compound-air-samples-suggest-b99505149z1-308183961.html/

6. Centers for Disease Control and Prevention. (2017, October). Coffee Roasting and Packaging Facilities. Flavorings-Related Lung Disease. Retrieved from: https://www.cdc.gov/niosh/topics/flavorings/processing.html

7. Anderson, K. E., Cornish, J., Greivell, J., Hoppe Parr, K. A., Haapala, M., & McCoy, M. J. (2017, January). Toxicology Reports. Retrieved from: https://www.ncbi.nlm.nih.gov/pubmed/28959632

8. Rutledge, Raquel. (2018, November). Q & A: A Primer on Hazards in Coffee Roasting Industry. Milwaukee Journal Sentinel. Retrieved from: https://www.jsonline.com/story/news/investigations/reports/2018/11/21/coffee-roasting-industry-hazards-explained/822459002/

9. Boylstein, R., McClelland, T., White, S.. (2018, October). Evaluation of Exposures and Respiratory Health at a Coffee Roasting and Packaging Facility. NIOSH Health Hazard Evaluation Report # 2016-0141-3329. Retrieved from: https://www.cdc.gov/niosh/hhe/reports/pdfs/2016-0141-3329.pdf

10. Hawley, B., Martin Jr., S. B., Nett, R. J., & Reynolds, L. (2018, January). Evaluation of Exposures and Respiratory Health at a Coffee Roasting and Packaging Facility. NIOSH Health Hazard Evaluation Report # 2016-0005-3303. Retrieved from: https://www.cdc.gov/niosh/hhe/reports/pdfs/2016-0005-3303.pdf

11. Raquel, Rutledge. (2015). Watchdog Report – Grasping for Action. Milwaukee Journal Sentinel. Retrieved from: http://archive.jsonline.com/watchdog/watchdogreports/gasping-for-action-b99440601z1-291548941.html/

12. Centers for Disease Control and Prevention. (2018, June). Occupational Exposure Limits. Flavorings-Related Lung Disease. Retrieved from: https://www.cdc.gov/niosh/topics/flavorings/limits.html

Made in the USA

Made in the USA