Whether you suffer from headaches after soldering or are trying to comply with OSHA regulations, certain considerations should be made before purchasing a solder fume extractor.

There is a wide range of solder fume extractors on the market priced from $45 to several hundred dollars. Before you are tempted by the price tag, consider why there is such a price gap.

We took four popular solder fume extractors priced around $100 or less, and compared them to our Sentry Air Stainless Steel Solder Sentry. Results are depicted in the chart below.

As you can see from the chart, there are two major differences between Sentry Air Systems’ Stainless Steel Solder Sentry and all the others.

- Filter Type

- Filter Placement

Filter Type

The Solder Sentry uses a HEPA filter ― with an efficiency rating of up to 99.97% on particles 0.3 microns and larger ― while the other four use a basic carbon or charcoal foam filter pad.

The Solder Sentry uses a HEPA filter ― with an efficiency rating of up to 99.97% on particles 0.3 microns and larger ― while the other four use a basic carbon or charcoal foam filter pad.

There are major differences between HEPA and Carbon filter media.

A very rudimentary comparison is that HEPA is designed to better filter particles (i.e. smoke, fume), while activated carbon is designed to better filter odors (i.e. volatile organic compounds, smelly chemicals).

While solder composition may vary, it usually contains 60-63% tin and 37-40% lead. Flux is also commonly used in soldering. When these materials are heated they can become volatized and emit fume, smoke and other airborne particles.

This smoke and fume contains particles as small as 0.5 – 1 micron in size. These particles pose the most serious health risk as they are considered respirable and can easily embed on the operator’s lungs.

Over time, respirable particle inhalation can lead to serious health effects including decreased function of the respiratory system, asthma, lung cancer and cardiovascular issues.

Simply put, fume extractors using only a basic carbon foam filter pad cannot effectively remove these microscopic particles. That is why fume extractors with high quality HEPA filter media are worth the investment.

Filter Placement

Another major difference between the Solder Sentry and the other four units is where the filter is placed in relation to the fan assembly.

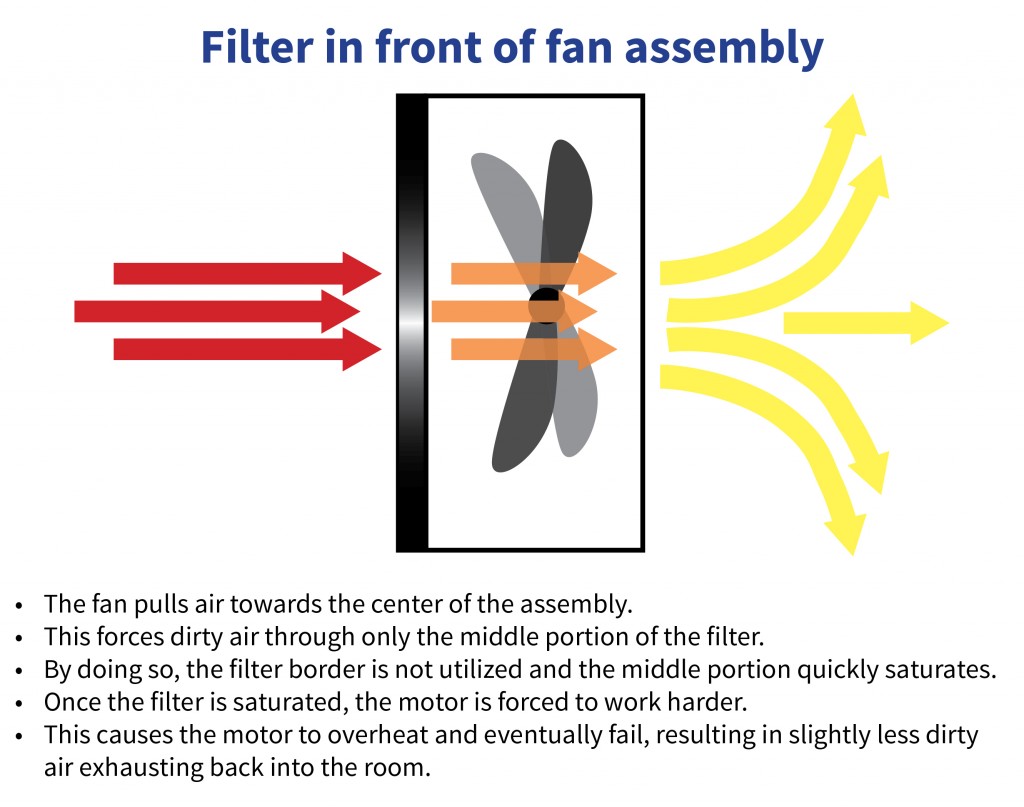

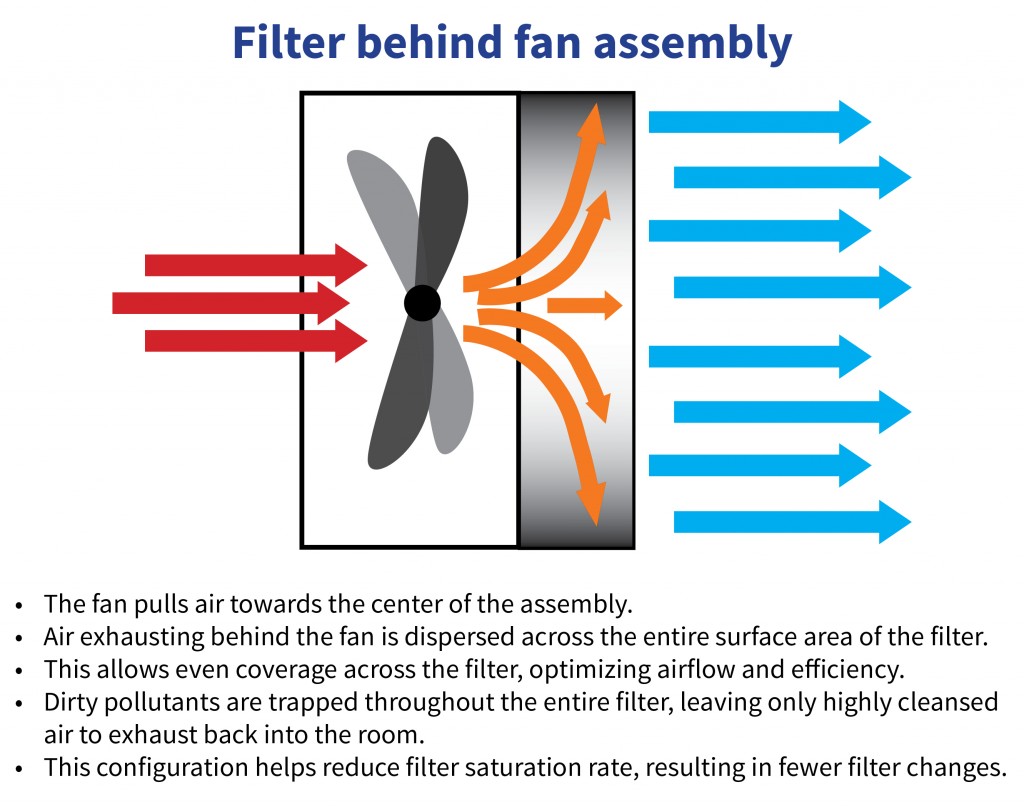

The Solder Sentry places the filter behind the fan while the others place their filter in front of the fan.

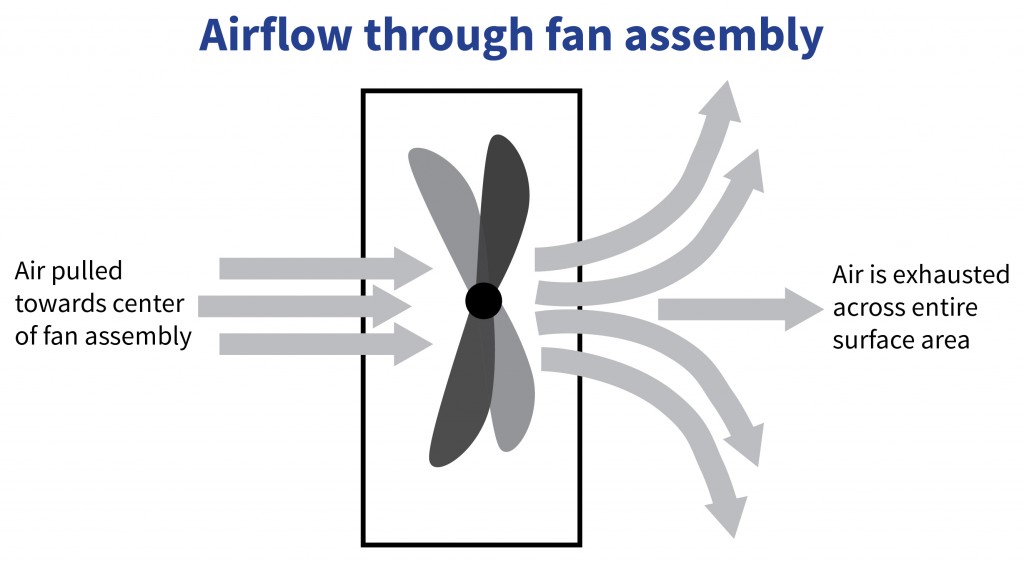

Why does this matter? Well first let’s consider how air travels through a fan assembly. As depicted in the graphic below, the fan motor pulls air towards the center of the assembly and exhausts air in a multi-directional outward flow.

This is an important consideration because, a filter’s performance and life expectancy are greatly affected by the direction and force of air.

Units with filters placed before the fan create a tunneling effect, resulting in only the middle portion of the filter being used. This quickly clogs the filter leading to an overheated fan motor, and minimally filtered air exhausting back into the room.

Instead, the Solder Sentry places the HEPA filter behind the fan assembly. The air leaving the fan housing is evenly dispersed across the entire surface area of the filter. This allows greater particle capture and highly cleansed air exhausting from the unit.

What next?

When shopping for a solder fume extractor, don’t base your decision solely on price.

It is important to remember why you are researching extractors to begin with – to remove the harmful fume you shouldn’t breathe!

Things to consider before purchasing a solder fume extractor:

- Filter, Filter, Filter – Only use a fume extractor with high quality HEPA filter media. Be sure to verify the filter’s efficiency rating as not all HEPA filters are the same.

- Airflow – The ratio of filter efficiency to air volume is important. Units with a powerful fan and low quality filter merely push contaminated air around. Conversely, units with a weak fan and high quality filter drastically reduce air pressure resulting in inefficient fume capture.

- Functionality – Size, weight, and operator use should be considered. Where are you soldering? What size is your work area? Are multiple operators soldering in one area? By answering these questions, the most appropriate fume extractor configuration can be determined.

- Maintenance – Consider the filter replacement costs associated with a fume extractor. In order to maintain proper filter efficiency and healthy working conditions, subpar filter media will need to be replaced at a higher rate than higher quality particulate filter media.

To see Sentry Air Systems’ entire line of Solder Fume Extractors, visit our website.

Additional Resources

***Product Comparison Report***: SAS Solder Sentry™ vs. Weller Smoke Absorber™

Technical Article: The Hazards of Solder Fume

SlideShare Presentation: Solder Fume Health Hazards

Blog: De-soldering fumes and respiratory safety

Blog: Solder Fume Extractors – How to choose the appropriate model

Blog: HEPA filters are not sieves

Graphic: HEPA Filter Particles Size Chart

Contact Us

For more information about solder fume control or to receive a free quote, give Sentry Air Systems a call at 800.799.4609, email sales@sentryair.com, visit our website or fill out the feedback form below.

Made in the USA

Made in the USA