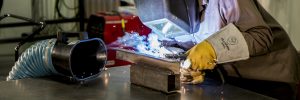

Welding produces hazardous fumes that must be controlled to safeguard employee respiratory and overall health. Welding exposes metals to high levels of heat creating gaseous fumes and nano-particles. The hazards of welding fumes depend on the contents of the metal, the type of welding process, and the frequency of welding. Fume extractors must be utilized… Learn More

Made in the USA

Made in the USA