While 3D printing has been used by medical professionals for the past decade, new software and technology has created a resurgence in popularity. Medical and surgical professionals turn to 3D printing for its accuracy, variety of printing material and availability in the marketplace.

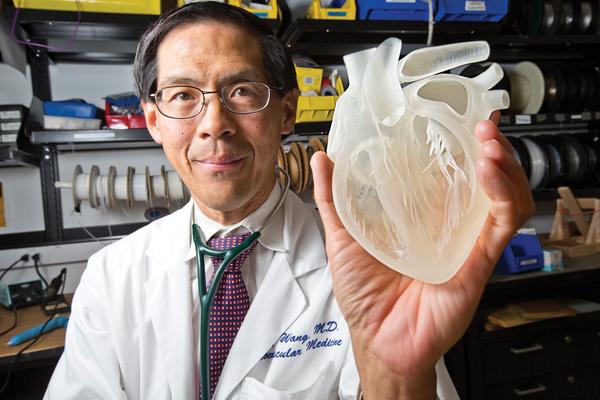

Photo Source: www.bizjournals.com – This resin heart, held by Stanford cardiologist Dr. Paul Wang, is the product of 3-D printing technology that may help advance medical breakthroughs.

Medical schools and training facilities print near perfect 3D plastic replicas of human body parts for educational and research purposes.

Even more incredible is the impact 3D printing is making on the operating table.

Traditional methods to prepare for surgery are modernizing to take advantage of this digital revolution.

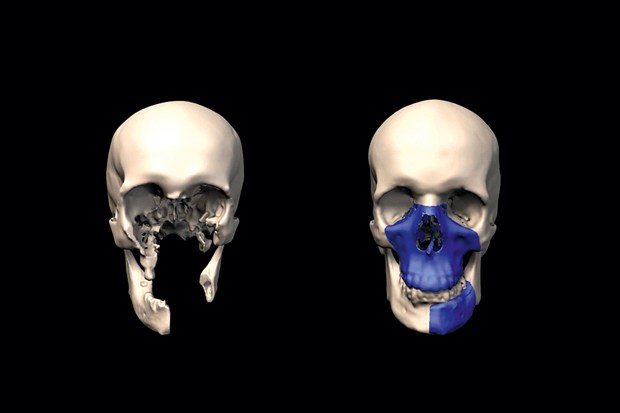

In an article entitled How 3D Systems’ Medical Modeling is Changing the Operating Room for the Better, Dr. Oren Tepper, Assistant Professor of Surgery at New York’s Montefiore Medical Center, said “the first real advancement was the CT scanner, which allowed plastic surgeons to look at bodies via the CT scans. Next, the skull was 3D printed so it could be used as a reference. The process started building stereolithographic models of the skulls so it was possible to study them in any direction and to practice surgery…Now, it is possible to plan a surgery on a computer for surgical simulation. Therefore, surgeons can move the bone structures where they want them to be and they can develop on the computer and 3D print guides and jigs which they sterilize and bring to the operating room.”

Photo Source: www.makerbot.com – A 3D model was created and printed in preparation for a patient’s upcoming facial transplant.

Before you hit ‘print’

Doctors, hospitals, and surgical facilities that use or are thinking of using 3D printers, may be unaware that the 3D printing process emits particles and fume that are not only a nuisance but potentially hazardous when inhaled.

In an earlier blog post, we discuss how ABS and PLA plastic filaments produce ultra-fine particles (UFP) when heated by a 3D printer. We also touch on a study which found that UFP, when inhaled, can deposit in the lungs and in the head’s airways.

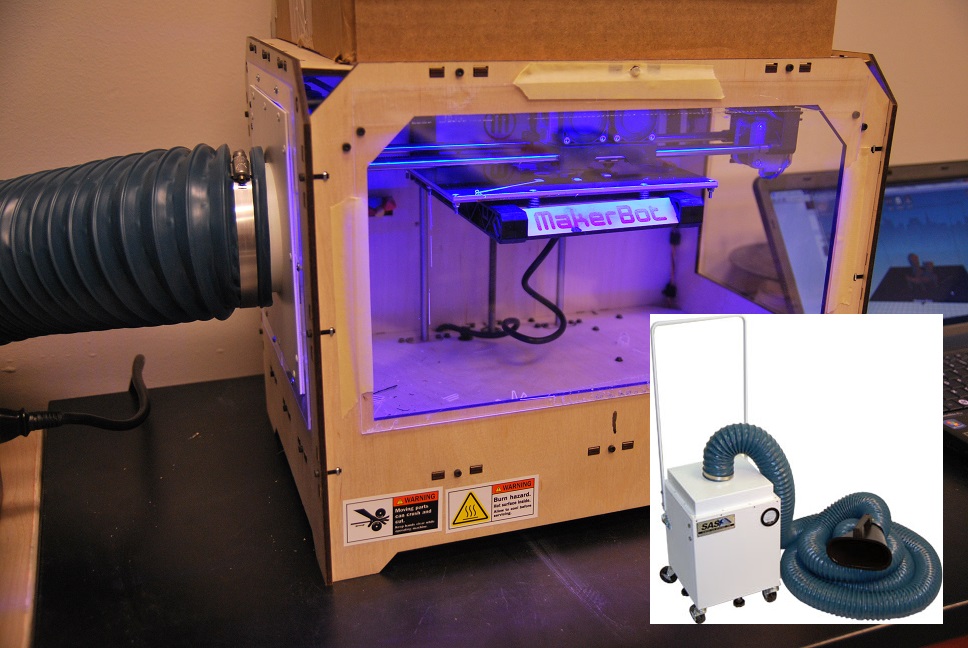

Photo Source: www.robotshop.com – MakerBot Replicator Desktop 3D Printer 5th Generation showing unenclosed print area

The most common route of exposure to plastic filament fume and UFP come from the open areas of the printer. By design, most desktop 3D printers have an unenclosed or semi-enclosed print area. While in operation, these open areas allow particles and fume to enter the ambient air.

If you need to print a complex implant design or to-scale replicas of a human bone, for example, that 3D printer could print for hours, emitting UFP the whole time.

Some filaments boast “low odor” or “styrene free” and while that may reduce nuisance burnt plastic smells, particles are still generated by heating and extruding the filament.

Beyond the print

Once an object has completed printing, additional steps must be done in what is called the “finishing process”.

This process varies depending on the object and its end use, but may involve removing excess dust or flakes, wiping down with a solvent and applying a polish or paint.

If the object is used as a medical implant, then a final sterilization step must be done in order to adhere to medical standards.

This entire finishing process produces a host of chemical odors and particulate that should be extracted.

Source capture and ambient engineering safety controls

Whether you 3D print on the 3rd floor of an office building, in a basement research lab or in an operating room, there are multiple fume extraction system configurations available to you by Sentry Air Systems.

Our most popular solutions for 3D fume control are our Model 300 Portable Floor Sentry and our Ductless Containment Hoods; both offering source capture fume extraction.

Our Model 700 free-hanging ambient air cleaner works as a secondary engineering safety control to scrub the ambient air of any renegade fume or particles.

Some common concerns we hear from those seeking 3D fume control are:

- Noise

- Air volume

- Exhaust air

- Flexibility

- Air Quality

Since the printer could run anywhere from 2 hours to 24/7, operators want a fume exactor that produces minimal noise. Secondly, the amount of air being pulled through the fume extractor is of concern. Too much airflow and the extruding filament may pull away from the desired print point before fully curing.

Thirdly, if you have to exhaust the fumes outside via the building’s ductwork, you are forced to create make-up air which is costly. Flexibility is also a concern because the printer may be placed in a small room or stringent facility requirements may limit placement options.

Sentry Air fume extractors quell each of these concerns through effective design.

Noise: Our 300 Series extractors run between 61-66 dBA (low to high) – similar to normal conversational speech decibel levels.

Air volume: Our Series 300 extractors come standard with a variable speed control knob (on 115V units). This gives the operator complete control over the amount of airflow between 0-350 CFM. *Read one of our customer’s tip in an earlier blog post.

Exhaust Air: Zero exterior exhaust is required for our 300 Series extractors. By utilizing a patented fan/filter chassis design, the units pull contaminated air through high quality filtration media before recirculating cleansed air into the ambient air. This ductless design saves thousands in potential ductwork and A/C costs.

Flexibility: Sentry Air fume extractors take modular design to a new level. Whether portable, wall mount, bench mount, stand mount, or a containment hood, our fume extractors come in a variety of configurations and their “plug-and-play” operation make relocating the unit a breeze.

Air Quality: This one is of particular importance to those in the medical/surgical field as air cleanliness is vital to overall patient health. Our 300 Series extractors feature a multi-filter chamber that can be customized to suite an application. Options include a carbon pre-filter pad, HEPA particulate filter (up to 99.97% efficient on particles down to 0.3 microns), and Activated Carbon filter for VOC and odor adsorption.

We invite you to visit our webpage and view the below picture gallery.

Medical Manufacturing: Air Purification Options (blog)

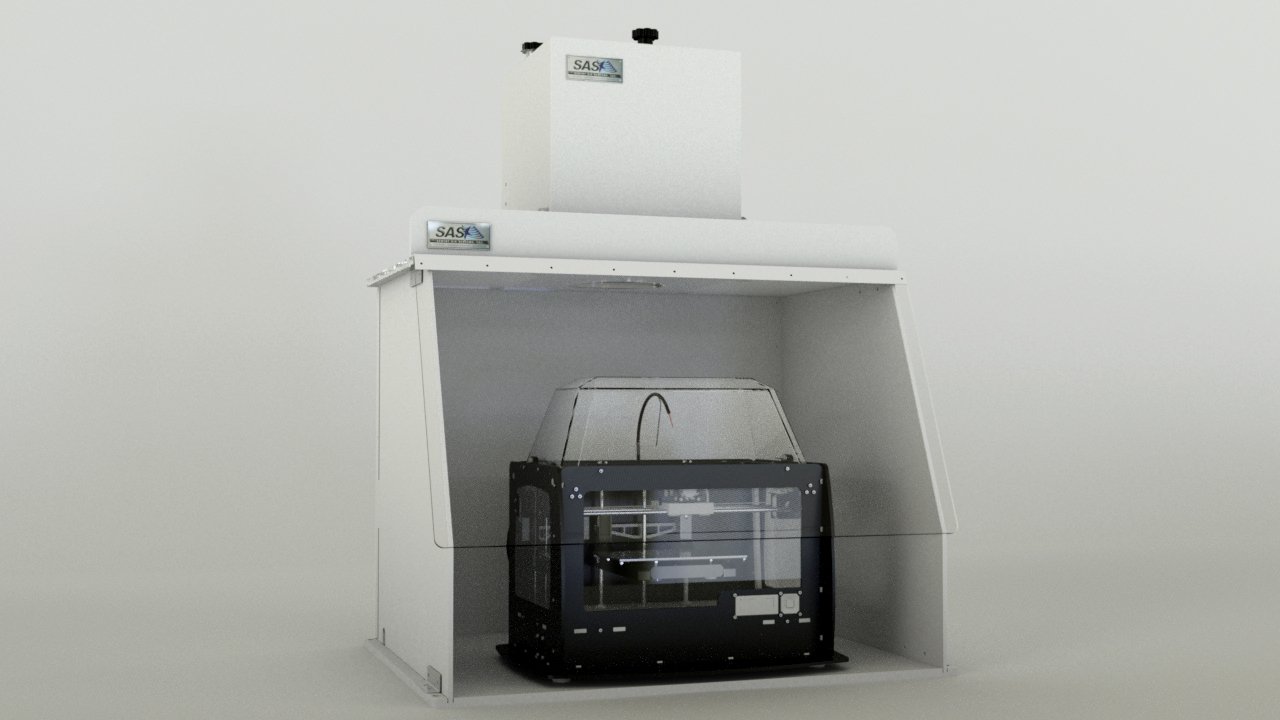

Conceptual drawing of a lab showing a variety of our ductless containment hoods, as well as our Model 200 SKY Sentry (mounted on far wall). A 3D printer can be placed inside these hoods for particle and fume capture.

A conceptual drawing of one of our standard ductless containment hoods with a MakerBot Replicator 2X 3D printer inside.

Our Model 300 Portable Floor Sentry with python-style flex hose is shown attached to the side panel of a MakerBot 3D printer at the Children’s Museum of Houston’s Maker Annex.

Contact Sentry Air

For more information or a free quote, contact Sentry Air at 800.799.4609, visit our website, email sales@sentryair.com or fill out the feedback form below.

Made in the USA

Made in the USA