Axonics Modulation Technologies is a California company that develops implantable devices to treat urinary and fecal dysfunction.

They recently emailed us about an unpleasant 3D printer fume problem that was solved with the help of a Sentry Air representative and the modular design principles basic to the Model 300 fume extractor.

The Odor Problem

We have a 3D printer in a large lab space that emits fumes as it cures. It made the room smell like chemicals and made the large lab space very unfavorable to work in. It resulted in a lot of complaints from coworkers.

The Fume Extractor Solution

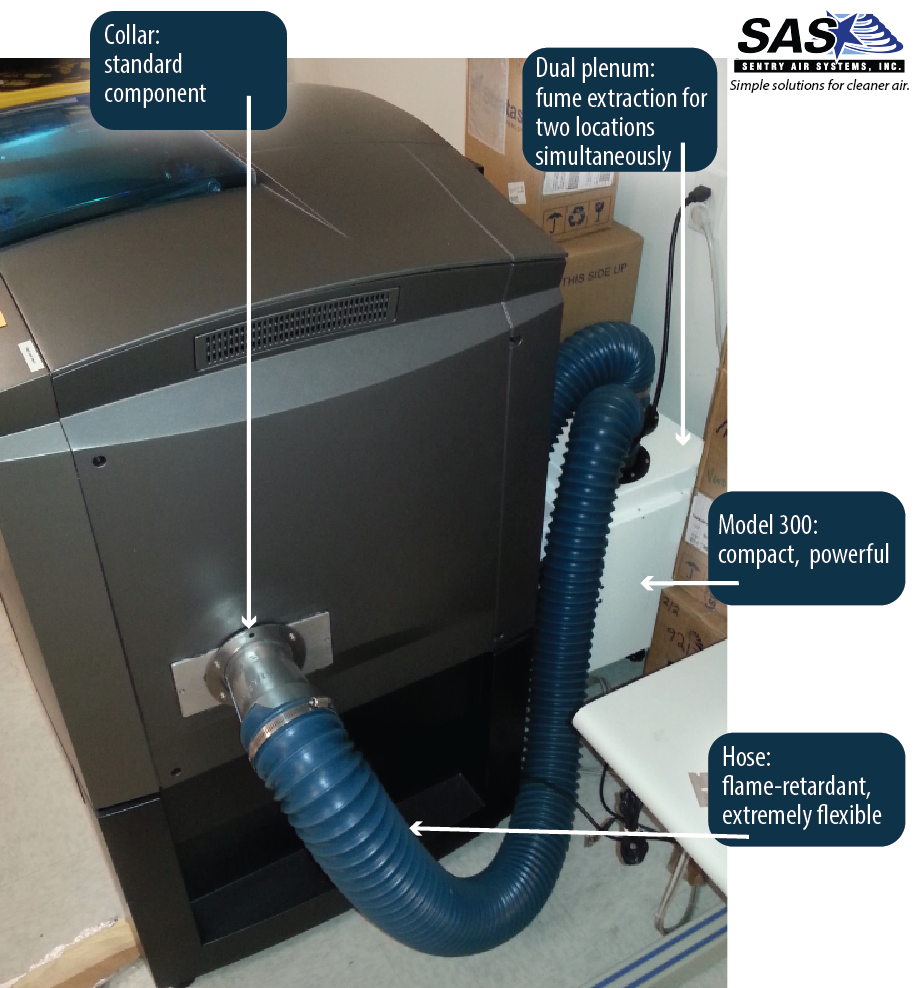

In this photo, you can see how lab personnel converted the printer’s exhaust grate to a fume extraction port, then attached a flexible python hose connected to a Model 300 behind the printer. For inspiration, they reviewed a similar process used by the Children’s Museum of Houston.

With help from Sentry Air application specialists, Axonics Modulation Technologies repurposed a Model 300 Portable Fume Extractor to be utilized for a 3D Printer.

Luckily we had the 300-PFS system on hand from a previous project. I worked with Adam from Sentry Air on how to set up the unit to filter the air coming out of two different exhaust outlets on the 3D printer.

Based on my needs, he set me up with a flexible dual hose and gave me information on how to connect the hoses to my printer’s exhaust outlets.

The outcome

The collar/hose combination shown here pulls fumes previously pushed into the lab into two filters, HEPA and activated carbon, in the Model 300 tucked behind the 3D printer.

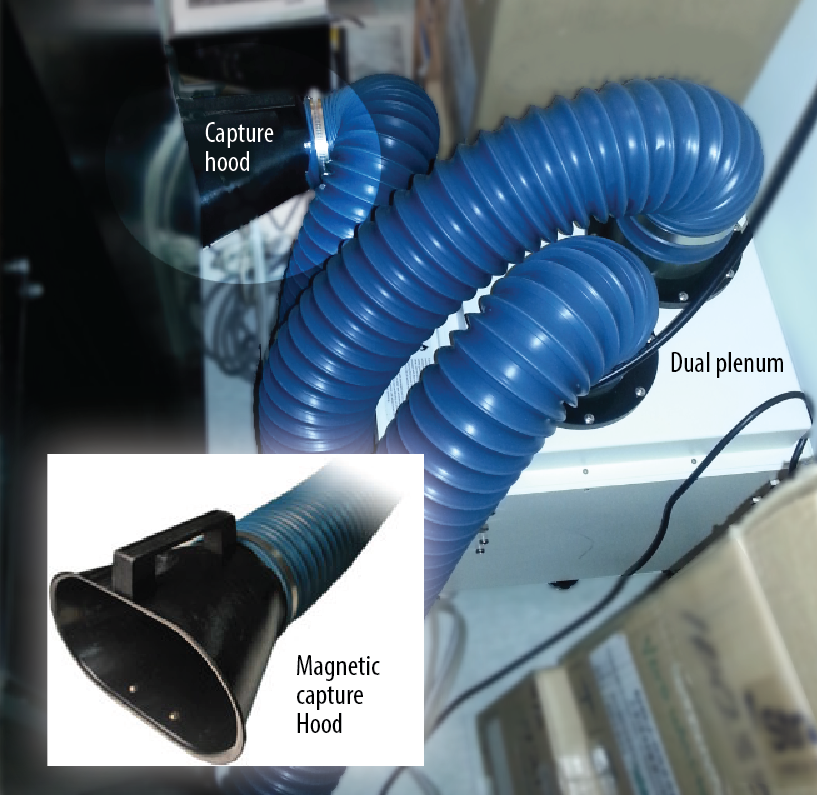

In this top down view, you can see the top of the dual plenum and a magnetic capture hood at the printer’s second exhaust site. The insert provides a more explicit view of the capture hood, a standard component from our catalog.

With the carbon and HEPA filters, we can run the 3D printer all day and the air smells chemical free! We run the unit 24/7 and after about 14 weeks we had to change the carbon filter, however, the HEPA filter is still going strong. The unit saved us from a huge headache since our building would not let us make changes to the air duct system (that would be very costly anyways).

Moving the 3D printer to a smaller room would not have been a viable option since the fumes would just be recirculating in the building. We are very happy and grateful to have found the solution that Sentry Air has provided for us!

— Kristi Clampitt – Axonics Modulation Technologies, Inc.

Modular systems provide solutions

At Sentry Air, we like it when we can work with a customer to help solve a dirty air problem.

The fact that Axionics workers could repurpose – with standard components, nothing custom made – their existing Model 300 into a dual-hose fume extractor for a 3D printer is a physical demonstration of provoking and well-planned product design.

To read more about our ductless fume extractors and 3D printing, see earlier blogs about counting particles and 3D printing at the Children’s Museum of Houston and our recent installation of an ambient air cleaner there.

We also have more information about the Model 300’s recent UL certification in our blog.

3D printing in your lab?

If you’re seeking appropriate ventilation for your lab and prototyping processes, and you don’t want to disrupt the physical surroundings, please give our applications specialists a call at 800.799.4609.

You can also email them at sales@sentryair.com, visit our website, or contact them on our contact form .

Resources

Need a fume exhaust port on your 3D printer? Here’s how to make one.

https://sentryair.com/blog/art-making/need-a-fume-exhaust-port-on-your-3d-printer-heres-how-to-make-one/

3D printing: Are there particles? How about fumes?

https://sentryair.com/blog/health/3d-printing-are-there-particles-how-about-fumes/

3D printing fume extraction for the medical and surgical industry

https://sentryair.com/blog/medical/3d-printing-fume-extraction-for-the-medical-and-surgical-industry/

Video: Biomedical engineers create 3-D model of heart

http://heart.phoenixchildrens.org/biomedical-engineers-create-3-d-model-heart

Ultrafine particle emissions from desktop 3D printers, by Brent Stephens, Parham Azimi, Zeineb El Orcha, Tiffanie Ramos Department of Civil, Architectural and Environmental Engineering, Illinois Institute of Technology, Chicago, IL, USA, National Institute of Applied Sciences (INSA de Lyon), Lyon, France

http://bit.ly/11RTixO

Nanotoxicology: An Emerging Discipline Evolving from Studies of Ultrafine Particles, Environ Health Perspect. 2005 July; 113(7): 823–839, by Günter Oberdörster, Eva Oberdörster, and Jan Oberdörster

http://www.ncbi.nlm.nih.gov/pmc/articles/PMC1257642/

Made in the USA

Made in the USA